Lockout and Tagging – Ensuring Workplace Safety

Introduction

Lockout and Tagging (LOTO) are critical safety procedures designed to protect workers from hazardous energy releases during the servicing and maintenance of machinery and equipment. These practices are essential for preventing serious injuries and fatalities caused by the accidental start-up of machinery or the unexpected release of stored energy. Understanding and adhering to LOTO procedures is not just a regulatory requirement but a moral obligation to ensure a safe working environment.

Why Lockout and Tagging Are Important

Every year, thousands of workers are injured or killed due to improper handling of machinery during maintenance activities. These incidents often occur because machinery is not properly shut off or isolated from energy sources, leading to unexpected movements or releases of energy. Lockout and Tagging procedures are designed to eliminate these risks by ensuring that machinery cannot be accidentally activated while workers are performing maintenance or repairs.

The Basics of Lockout and Tagging

- Lockout:

- Definition: Lockout refers to the process of isolating energy sources by locking the controls in the “off” position, preventing the accidental activation of machinery or equipment.

- Process: A lock, typically a padlock, is placed on the energy isolation device (such as a breaker, valve, or switch) to hold it in the “off” position. Only the worker who applied the lock can remove it, ensuring complete control over the system.

2. Tagging:

- Definition: Tagging involves attaching a tag to the locked-out energy isolation device that indicates the equipment is under maintenance and should not be operated.

- Process: The tag is a visual warning that identifies the worker who applied the lock and provides information about the work being done. While a tag alone does not provide physical restraint, it is a crucial part of the LOTO procedure as it communicates the status of the equipment to other workers.

Key Elements of an Effective Lockout and Tagging Program

- Preparation:

- Identify All Energy Sources: Before any maintenance work begins, it’s vital to identify all potential energy sources that could cause harm, including electrical, mechanical, hydraulic, pneumatic, chemical, and thermal energy.

- Develop Procedures: Establish specific LOTO procedures for each piece of equipment, detailing how to isolate and lock out energy sources.

2. Training:

- Employee Training: All employees must be trained on the LOTO procedures relevant to their work. This includes recognizing hazardous energy sources, understanding the methods of isolating and controlling these sources, and knowing how to apply and remove locks and tags.

- Retraining: Regular retraining is necessary, especially when there are changes in job assignments, equipment, or processes, or if the LOTO procedures are updated.

3. Execution:

- Notify Affected Employees: Before beginning lockout procedures, inform all affected employees that the machinery or equipment will be shut down and locked out.

- Shutdown and Isolation: Shut down the equipment following established procedures. Isolate all energy sources, ensuring that there is no possibility of residual or stored energy remaining.

- Apply Lockout Devices: Attach locks to all energy isolation devices. Each worker involved in the maintenance should apply their lock, ensuring that no single person can accidentally re-energize the system.

- Tagging: Attach tags to the locks with clear information indicating the reason for the lockout, the worker responsible, and the date. Tags should be durable and securely attached to prevent removal.

4. Verification:

- Test the Isolation: After applying locks and tags, verify that the equipment is properly isolated by attempting to operate the controls. Ensure that no energy is released and the equipment cannot be turned on.

5. Perform Maintenance:

- Proceed with Work: Once verification is complete, maintenance or repair work can be safely performed on the equipment.

6. Restoration of Equipment:

- Inspection: After completing the maintenance, inspect the equipment to ensure all tools and materials have been removed and the system is intact.

- Remove Locks and Tags: Only the worker who applied the lock should remove it. If multiple locks were applied, each worker must remove their lock in the correct sequence.

- Re-energize Equipment: After all locks and tags are removed, re-energize the equipment and notify affected employees that the equipment is back in operation.

Common Mistakes to Avoid

- Skipping Procedures: Never take shortcuts in the LOTO process, even if it seems like it will save time. Skipping steps can lead to accidents.

- Inadequate Training: Ensure all employees understand the importance of LOTO procedures and are properly trained to carry them out. Untrained workers are a significant hazard.

- Miscommunication: Always communicate clearly with all affected employees. Failure to notify others about locked-out equipment can result in unintended activation.

- Improper Use of Tags: Tags must be securely attached and legible. They should include all necessary information and should never be removed by someone other than the person who applied them.

Conclusion

Lockout and Tagging are vital safety practices that protect workers from the dangers of hazardous energy. By strictly adhering to LOTO procedures, you not only comply with regulations but also create a safer work environment where everyone can confidently perform their duties. Remember, safety is a shared responsibility, and taking the time to properly lock out and tag equipment can save lives. Always prioritize safety, follow procedures, and ensure that you and your colleagues return home safely at the end of each day.

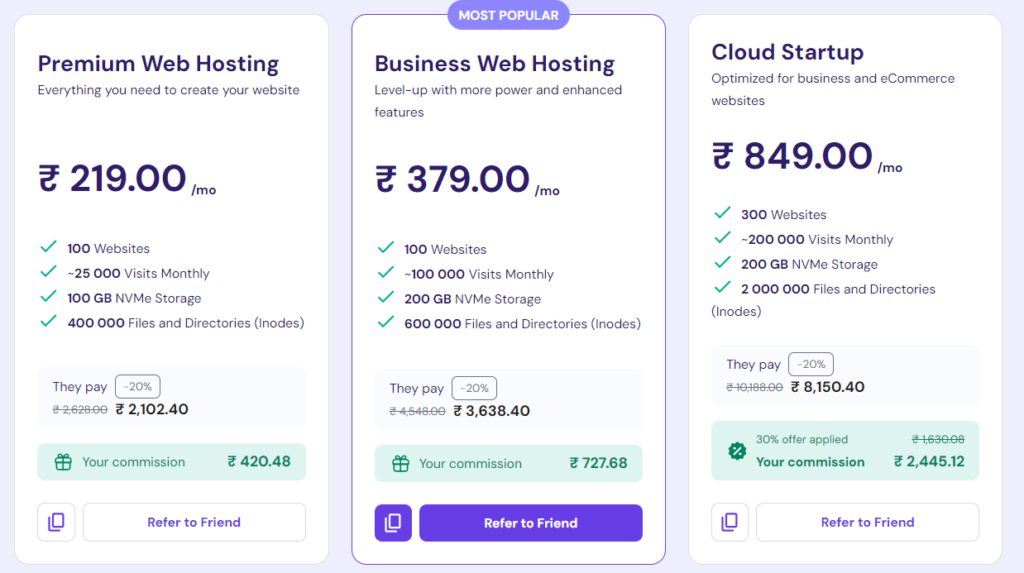

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”