Occupational Health & Safety Provisions Under the Factories Act – And How to Practically Implement Them on the Shop Floor

Introduction

In today’s industrial environment, occupational health and safety (OHS) isn’t just about compliance—it’s about caring for people. Workers are the backbone of any factory setup, and ensuring their safety is not only a legal obligation but a moral one too.

The Factories Act, 1948 provides a comprehensive framework for ensuring health, safety, and welfare of workers in Indian factories. However, the real challenge lies in translating the legal provisions into practical, everyday actions on the shop floor.

In this blog post, we’re breaking down key health and safety provisions under the Factories Act, and more importantly, discussing how to actually implement them on the ground. This guide is especially useful for EHS managers, safety officers, plant heads, and HR professionals involved in factory operations.

🏭 What is the Factories Act, 1948?

The Factories Act, 1948, is a central legislation in India designed to regulate the working conditions in factories. It emphasizes:

- Ensuring occupational safety and health

- Regulating working hours

- Providing welfare measures

- Enforcing minimum standards in factories

Any premises where 10 or more workers are employed with power, or 20 or more without power, and where a manufacturing process is carried out, comes under this Act.

🔍 Why Safety Provisions Matter

Let’s face it—accidents and occupational diseases can cost lives, money, and reputation. Every year, thousands of workers in India suffer due to preventable incidents. Enforcing safety isn’t just compliance; it’s good business.

“Safety brings first aid to the uninjured.” – F.S. Hughes

The law exists to create a safety net—but it’s up to factory management to bring it to life.

🧑⚕️ Health Provisions Under the Factories Act

1. Cleanliness (Section 11)

Provision: Factories must be kept clean and free from effluents, dust, and dirt.

Practical Implementation:

- Daily housekeeping schedules

- Dedicated cleaning staff on each shift

- Floor cleaning logs verified by supervisors

- Dust suppression systems near grinding or cutting areas

2. Disposal of Waste and Effluents (Section 12)

Provision: Effective arrangements must be in place for the disposal of waste and effluents.

Practical Steps:

- Install ETP/STP systems

- Regular sampling and testing

- Display effluent discharge data publicly

- Train workers not to mix hazardous and non-hazardous waste

3. Ventilation and Temperature (Section 13)

Provision: Ensure adequate ventilation and temperature control for worker comfort.

On-the-Floor Implementation:

- Use industrial exhaust fans

- Conduct monthly indoor air quality checks

- Thermal insulation on roofing sheets

- Provide rest zones with fans or cooling systems

4. Dust and Fume Control (Section 14)

Provision: Effective measures must be taken to prevent the inhalation of dust and fumes.

Implementation:

- Use LEV (local exhaust ventilation)

- Provide N95 respirators or dust masks

- Schedule fume-exposed tasks on rotating shifts

- Routine maintenance of exhaust chimneys and ducts

🛡️ Safety Provisions Under the Factories Act

1. Fencing of Machinery (Section 21)

Provision: All dangerous parts of machines must be securely fenced.

Implementation Steps:

- Use physical guards with interlock switches

- Conduct weekly audits to check for tampering

- Place signage: “Do Not Operate Without Guard”

2. Work on or near Machinery in Motion (Section 22)

Provision: Only trained adult male workers can work on machines in motion.

How to Enforce:

- Display SOPs near each machine

- Maintain training registers

- Lockout/Tagout (LOTO) kits available at each workstation

3. Employment of Young Persons on Dangerous Machines (Section 23)

Provision: Young workers must not operate dangerous machines without supervision.

Shop Floor Best Practices:

- Color-coded ID cards for age classification

- Assign mentors for young workers

- Supervisor sign-off before machine use

4. Safety of Buildings and Machinery (Section 40)

Provision: Ensure structural stability and mechanical integrity.

Practical Actions:

- Structural audits by certified engineers

- Preventive maintenance calendar for all machinery

- Load rating signs on mezzanines, platforms, and storage racks

5. Precautions Against Fire (Section 38)

Provision: Factories must take adequate precautions against fire and provide means of escape.

Fire Safety Implementation:

- Fire extinguisher layout every 15m

- Conduct quarterly mock drills

- Install fire alarms and smoke detectors

- Evacuation maps in all departments

💆 Welfare Provisions – Because Workers Deserve More

1. Washing Facilities (Section 42)

Provide clean and accessible wash areas for both men and women.

2. First Aid Appliances (Section 45)

One first aid box per 150 workers, maintained and checked weekly.

3. Canteen (Section 46)

Mandatory if 250+ workers are employed.

4. Shelters/Rest Rooms (Section 47)

For factories with 150+ workers. Must be well ventilated and clean.

5. Creche (Section 48)

If 30+ women workers are employed, a creche must be available.

Implementation Tips:

- Assign HR to conduct monthly inspections of welfare amenities

- Use feedback forms from employees

- Regular third-party hygiene audits

📋 Compliance + Culture = Safe Shop Floor

Compliance alone won’t prevent accidents—safety culture will.

🧠 Build Awareness:

- Use toolbox talks, safety posters, and floor markings

- Celebrate “National Safety Week” with contests and training

👩🏫 Train and Retrain:

- Conduct monthly refresher sessions

- Use bilingual or regional language content

🗣 Encourage Reporting:

- Reward near-miss reporting

- Make anonymous suggestion boxes available

🧰 Involve Everyone:

- Set up Safety Committees under Section 41G

- Include workers in safety audits and inspections

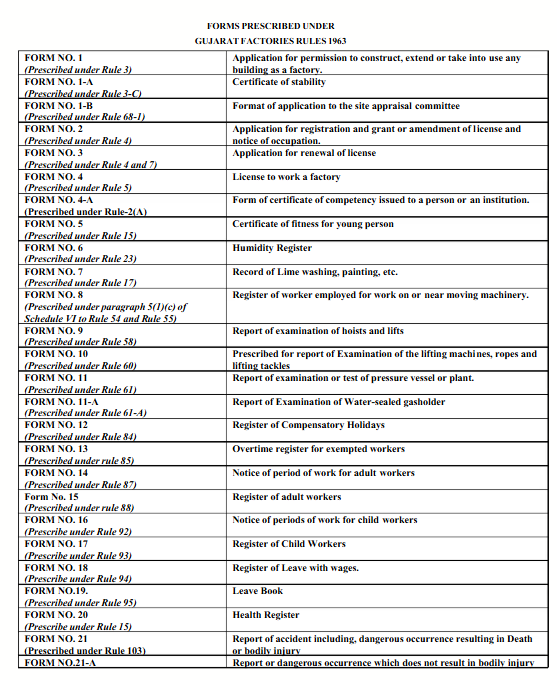

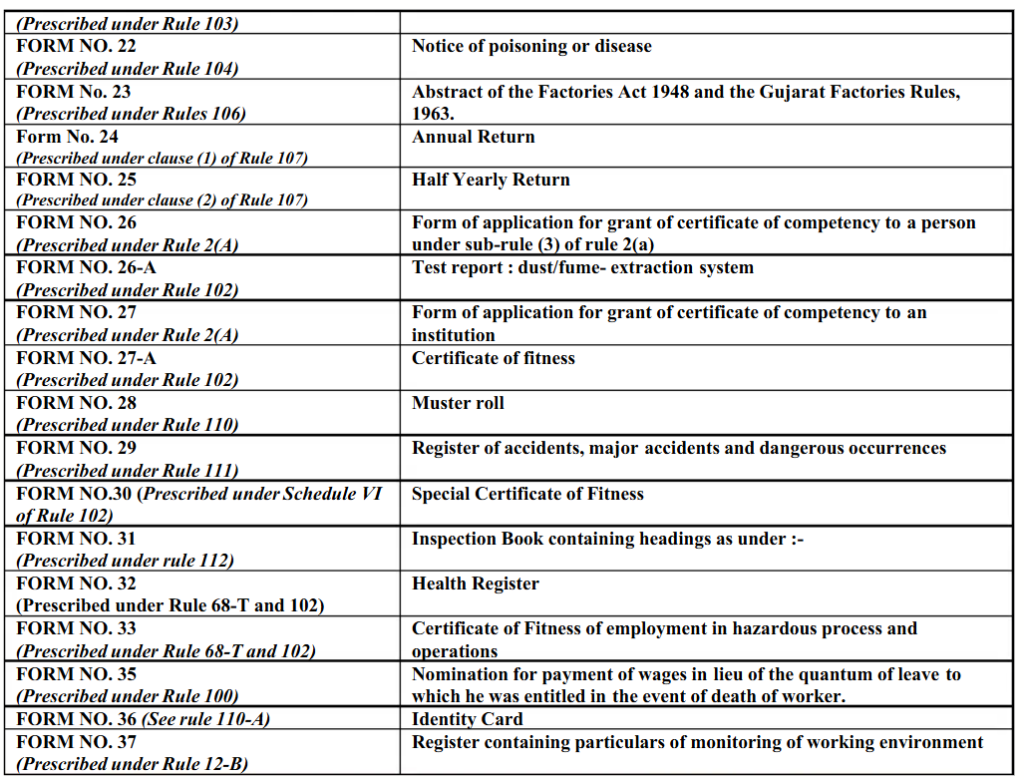

🧾 Documentation Required for Legal Compliance

Make sure the following are always updated and readily available:

🧠 Case Study: How One Factory Reduced Accidents by 70%

A mid-sized auto components plant in Gujarat implemented the following:

- Appointed a dedicated safety steward per shift

- Digitized safety audits with QR code-based checklists

- Used TV screens in the canteen to run safety awareness videos

Result?

- Lost-time incidents dropped from 12/year to 4/year

- Workers began proactively reporting hazards

- ISO 45001 certification achieved in 18 months

🔧 Safety Doesn’t Cost – It Pays

Still thinking safety costs too much?

Consider the cost of non-compliance:

- ₹1 lakh+ fines per violation

- Factory shutdowns

- Legal liabilities

- Worker unrest and bad PR

A safe shop floor = higher morale + fewer interruptions + better quality output.

✅ Action Checklist for Safety Implementation

Here’s a quick to-do list for EHS managers:

✔ Conduct a safety gap analysis vs. Factories Act requirements

✔ Assign safety responsibilities by department

✔ Create yearly training calendar

✔ Perform monthly internal audits

✔ Display mandatory safety signage

✔ Set monthly safety KPIs (e.g., near misses, incidents)

✔ Review performance in monthly management review meetings

📣 Final Thoughts: Compliance Is Only the Beginning

The Factories Act gives you the foundation—but it’s the commitment of your team that builds a true safety culture.

When workers feel safe, they perform better. When you walk the talk, safety becomes everyone’s priority—not just the safety officer’s.

So, let’s go beyond checkboxes. Let’s make safety real, visible, and practical—right where it matters most: on the shop floor.

👉 Have questions or want a downloadable checklist for shop floor safety implementation? Drop a comment below or subscribe for our upcoming “Safety Toolkit for Indian Factories.”

📌 Stay Safe. Stay Compliant. Stay Ahead.

🔁 Readers also enjoyed these blog posts:

- Safety Management’s Role: The Unsung Hero Behind Every Successful Organization

- Safety Management and Its Responsibilities: Protecting People, Preventing Hazards, and Promoting a Culture of Care

- Benchmarking for Safety Performance: A Key to Continuous Improvement

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”

Turn Any Idea into Viral,

Jaw-Dropping AI Videos in Seconds!