Wire rope cable clips are essential hardware used to secure the ends of wire ropes in lifting, rigging, and other industrial applications. When improperly installed, they can lead to serious safety hazards, including load failure, injury, or equipment damage. This blog will cover the importance of correctly using cable clips, installation guidelines, and common safety tips.

Here are 25 safety points for wire rope and cable clip use in the workplace:

General Safety

1. Inspection Before Use: Always inspect wire ropes and cable clips for signs of damage, corrosion, or wear before use.

2. Proper Storage: Store wire ropes and clips in a clean, dry area to prevent rust and corrosion.

3. Avoid Overloading: Do not exceed the recommended load limit of the wire rope or the cable clips.

4. Use the Right Type of Rope: Choose the correct wire rope based on the application (e.g., load requirements, environmental conditions).

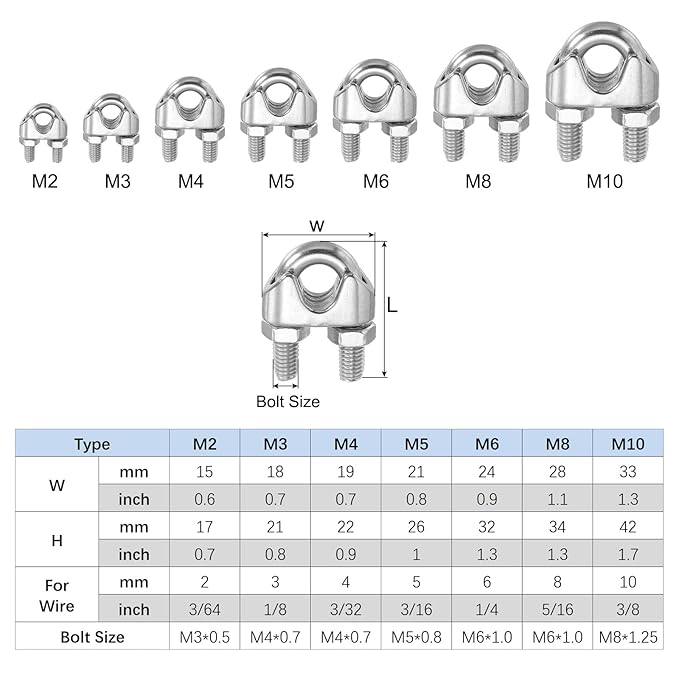

5. Use Compatible Clips: Always use cable clips that are suitable for the diameter and type of wire rope.

Cable Clip Installation

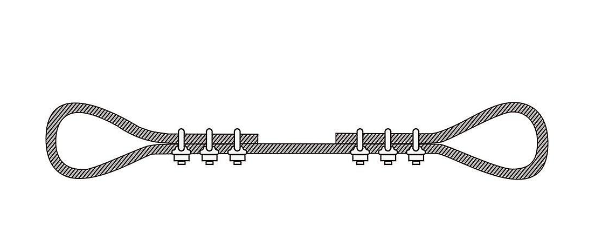

6. Proper Orientation: Install cable clips correctly, with the saddle on the live end of the rope and the U-bolt on the dead end (“Never saddle a dead horse”).

7. Correct Number of Clips: Follow the manufacturer’s recommendations for the number of clips required for the rope diameter.

8. Spacing Between Clips: Space the clips properly to ensure even distribution of the load.

9. Tightening Torque: Tighten the nuts on the cable clips to the recommended torque to secure the rope firmly.

10. Re-Tightening After Use: Re-tighten cable clip nuts after initial use and periodically thereafter, especially in dynamic applications.

3/8″ / 10mm Wire Rope Cable Clip Clamp, 4Pcs M10 304 Stainless Steel U Bolt Saddle Fastener for Rigging Railing, Silver Tone

Handling and Maintenance

11. Avoid Kinking: Never allow the wire rope to kink, as this can significantly reduce its strength.

12. Use Proper Tools: Use appropriate tools, like wire rope cutters and torque wrenches, to avoid damaging the rope.

13. Avoid Abrasive Surfaces: Keep wire ropes away from sharp edges and abrasive surfaces that could damage the strands.

14. Regular Inspection: Schedule routine inspections of the wire rope and cable clips to detect any signs of wear or damage early.

15. Proper Disposal: Dispose of damaged or worn-out wire ropes and clips according to safety guidelines.

Safety During Operation

16. Secure the Load Properly: Make sure that the load is evenly distributed along the wire rope.

17. Avoid Sudden Jerks: Do not subject the wire rope to sudden jerks or impacts, which can cause failure.

18. Use Safety Gear: Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, while handling wire ropes.

19. Avoid Over-Bending: Do not bend the wire rope excessively, as it may weaken the structure.

20. Stay Clear of the Load Path: Keep yourself and others away from the path of the load to avoid injury in case of rope failure.

Training and Awareness

21. Training for Personnel: Ensure that all personnel handling wire ropes and cable clips are adequately trained on proper techniques and safety procedures.

22. Communicate Load Limits: Clearly communicate the load limits and proper usage of wire ropes to all workers involved.

23. Display Safety Signage: Place warning signs in areas where wire ropes are used to remind workers of potential hazards.

24. Use Checklists: Utilize safety checklists to ensure all safety procedures are followed before, during, and after wire rope use.

25. Emergency Procedures: Have emergency procedures in place in case of wire rope or clip failure.

Following these safety points helps ensure that wire ropes and cable clips are used safely and effectively in the workplace.

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”