Hoisting operations are a crucial aspect of many construction and industrial activities, where loads are lifted and moved using cranes, hoists, or other lifting equipment. The safety and efficiency of these operations largely depend on effective communication between the crane operator and the signal person. This is where the importance of hoisting signals and ground rules comes into play.

In any hoisting operation, a qualified and authorized signal person is responsible for conveying instructions to the crane operator through standardized hand signals. This ensures that the operator is aware of when to lift, lower, stop, or move the load in specific directions. Properly established ground rules, such as using only one designated signal person at a time, maintaining a clear line of sight, and ensuring the use of standard signals, help prevent accidents and misunderstandings.

Workers involved in the lifting process should be trained in the recognition and use of hand signals, and everyone on the site should understand that the stop signal is universal and can be used by anyone to halt the operation in case of danger. To further enhance safety, all lifting equipment should undergo regular inspections, and communication equipment should be tested before use. Additionally, signal persons must wear high-visibility gear to ensure they are easily seen.

Following these hoisting signal ground rules not only ensures compliance with safety regulations but also helps create a safer work environment where accidents are minimized, and productivity is maintained.

Here are 25 points for a safety talk on hoisting signals, emphasizing the ground rules:

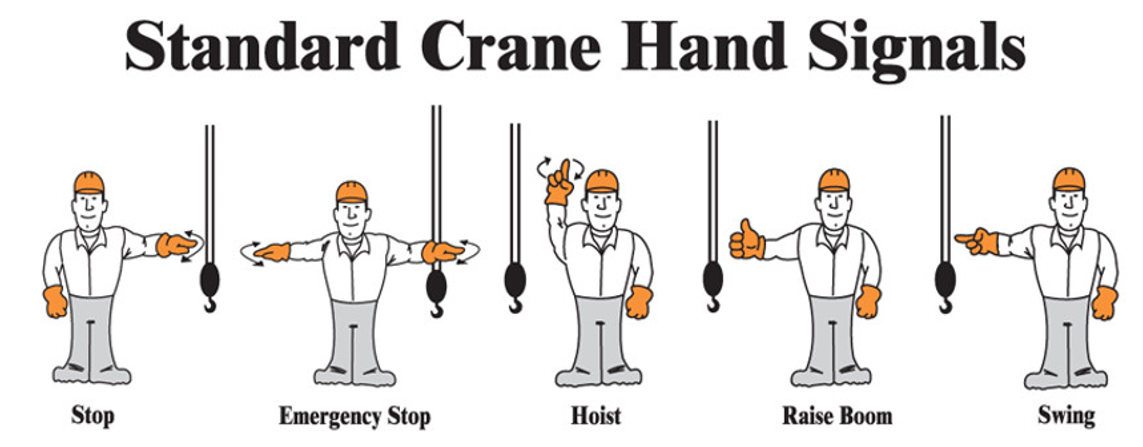

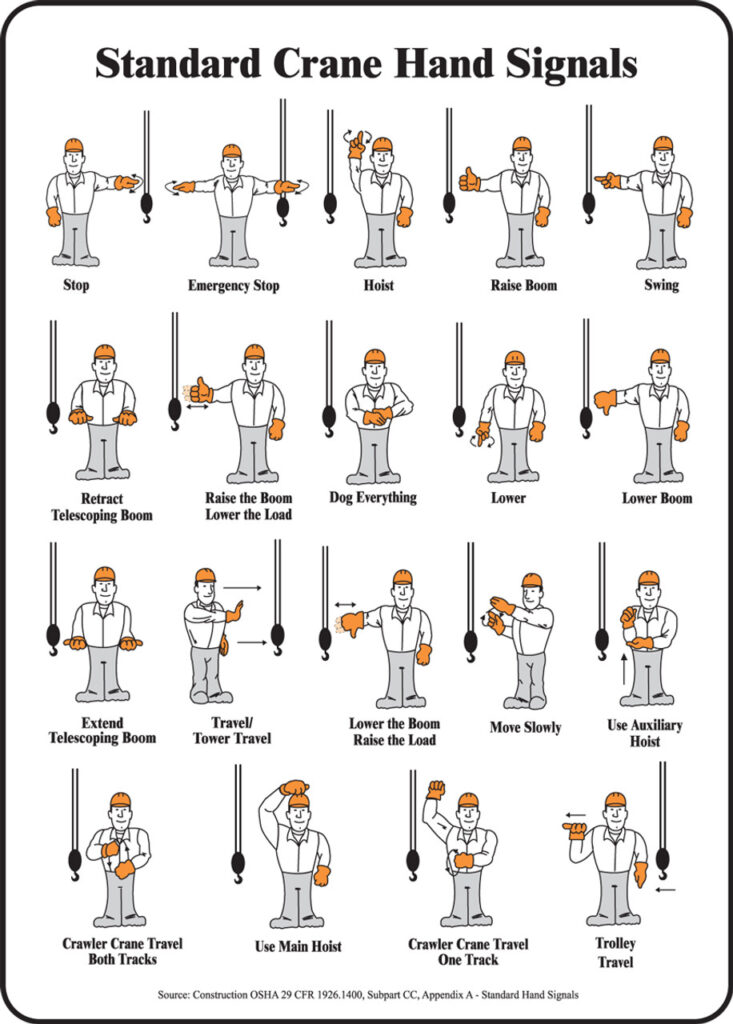

1. Standard Hand Signals

– Use standard hand signals for all hoisting operations, as outlined by safety regulations (e.g., OSHA or local standards).

2. Qualified Signal Person

– Only a qualified and authorized signal person should communicate with the crane operator.

3. Clear Line of Sight

– Ensure there is always a clear line of sight between the signal person and the crane operator.

4. Establish a Communication Plan

– Prior to the lift, establish a communication plan to clarify who will give the signals and how they will be given.

5. Designate One Signal Person at a Time

– Only one person should give signals to the crane operator to avoid confusion.

6. Stop Signal is Universal

– Anyone on the job site has the authority to give a stop signal if a hazardous condition is observed.

7. Review Signals with All Crew Members

– Before starting work, review the hand signals with all crew members involved in the lift.

8. Crane Operator Must Acknowledge Signals

– Ensure the crane operator acknowledges each signal before performing the lift.

9. No Signal, No Movement

– If the operator does not receive a clear signal, no movement should be made until communication is re-established.

10. Emergency Procedures

– All personnel should be aware of emergency signals and procedures in case of unexpected situations.

11. Communication Equipment

– If using communication devices (radios, etc.), ensure they are functioning correctly and set to the correct channel.

12. Safe Distance from Load

– The signal person and other workers should stay clear of the load’s path to avoid being struck by the load or equipment.

13. Visibility Gear

– Signal persons should wear high-visibility gear to ensure they are clearly seen by the operator.

14. Signal Consistency

– Always use consistent hand signals to avoid any misinterpretation by the operator.

15. Blind Spots Awareness

– Be aware of crane blind spots and ensure that the signal person positions themselves where they can be seen clearly.

16. Maintain Eye Contact When Possible

– The signal person should maintain eye contact with the crane operator whenever possible.

17. Avoid Distractions

– The signal person should not be engaged in other activities or distracted while giving signals.

18. Stop for Confusion

– If at any point the operator or signal person is confused, stop the operation until the situation is clarified.

19. Know the Weight Limits

– Ensure the load does not exceed the crane’s lifting capacity. Communicate load weight to the crane operator.

20. Hand Signal Training

– Workers involved in hoisting operations should receive proper training in recognizing and understanding standard hand signals.

21. Weather Considerations

– Stop hoisting operations if visibility is poor due to weather conditions, such as fog, rain, or snow.

22. Routine Inspections of Equipment

– Ensure all lifting equipment and communication devices are inspected regularly and in good working condition.

23. Avoid Standing Under Loads

– Never stand directly under a suspended load, and ensure the path is clear for the lift.

24. Signaling in Limited Visibility Conditions

– Use alternative methods, such as radios or horns, when visibility is limited, but ensure the signals are still clear.

25. Continuous Safety Assessment

– Constantly assess the situation for new hazards and adjust signals or procedures as necessary to maintain safety.

These points help ensure a safe and efficient lifting operation by emphasizing communication, training, and situational awareness.

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”