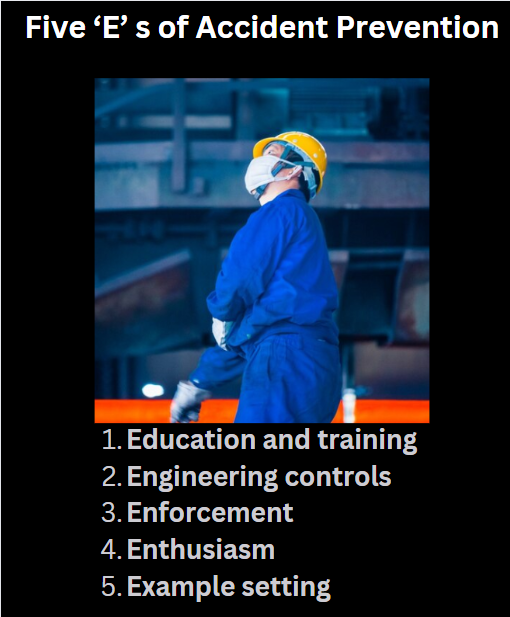

►Education and training (To prevent unsafe acts):

This has long term and permanent effect. This is the most powerful remedy for unsafe act of the workers. It helps in finding out unsafe conditions also. The workers’ safety training programmes should include (a) understanding of specific hazards of their plant, process, building etc. (b) safety rules and safe procedures (c) training for specialized or difficult job (d) job safety analysis (e) safety instruction for variety of jobs.

►Engineering controls (To prevent unsafe conditions):

Poor illumination and ventilation, unguarded machinery, mechanical, electrical, physical and chemical hazards, dangerous location and situation etc. are unsafe conditions which can be eliminated in the design stage or subsequent engineering revision and controls.

►Enforcement (Of safety rules):

All statutory safety provision should be followed by our own safety and safety of others. Self initiation for full compliance is necessary; otherwise government authorities may take action. Willful neglect or disobey of safety rules or orders should be dealt with strictly. Enforcement measures include-new law, amendment in old law, company safety rules, implementation and legal actions.

► Enthusiasm (To maintain interest):

Like a catalyst it adds to safety awareness and motivation. It should come from the top management to the lowest worker. It will keep the workers safety conscious. It can be developed and maintained by proper safety attitude, competition, prizes, awards, incentives etc.

►Example setting (To lead for safety):

The top executives, managers and supervisors should set an example to others by self enforcement of safety rules. Then other will follow them. This is the chain reaction to increase and maintain safety.