Introduction

When we talk about workplace safety, most people immediately think of heavy machinery, PPE, or fire hazards. But one often-overlooked danger quietly lurks in many workplaces—lighting. More specifically, the issues of flicker and the stroboscopic effect.

While these might sound like technical terms only engineers care about, they have real consequences for worker safety, productivity, and health. In this article, we’ll break down what flicker and stroboscopic effects are, why they happen, their risks, and how industries can effectively control them.

💡 What Is Flicker in Lighting?

Simply put, flicker is the rapid variation in light intensity over time. If a light is not steady, our eyes perceive it as flicker.

- Visible flicker: Obvious to the naked eye, usually at low frequencies (<80 Hz).

- Invisible flicker: Occurs at higher frequencies (80–3000 Hz) and may not be consciously noticed, but can still cause problems.

Common Sources of Flicker

- Fluorescent lamps: Older fluorescent tubes without electronic ballasts can flicker noticeably.

- LED lights: Cheap or poorly designed LED drivers may create flicker.

- Dimming systems: Some dimmers can introduce flicker in both LED and fluorescent lighting.

- Voltage fluctuations: Unstable electricity supply can lead to rapid intensity changes.

⚡ What Is the Stroboscopic Effect?

The stroboscopic effect is closely related to flicker, but its impact is particularly dangerous in industrial settings.

- It occurs when moving objects are illuminated by flickering light, making their motion appear slow, stationary, or even reversed.

- This optical illusion can mislead workers, resulting in accidents or injuries.

Example in Real Life

Imagine a rotating fan or a conveyor belt under flickering light:

- Instead of moving smoothly, the blades or objects may appear frozen or moving backward.

- Workers may misjudge speed or position and attempt adjustments, leading to serious accidents.

🛠 Why Flicker and Stroboscopic Effects Matter in Safety

Even if flicker is not obvious, it can cause subtle but cumulative problems.

- Health and Comfort Issues

- Headaches, eye strain, and fatigue.

- Nausea and dizziness in sensitive individuals.

- Sleep disturbances when exposed to flickering light for long periods.

- Reduced Productivity

- Invisible flicker can make tasks requiring precision more difficult.

- Mental fatigue sets in faster under unstable lighting.

- Accident Risk

- In manufacturing or machinery-heavy workplaces, stroboscopic effects can hide moving hazards.

- Workers may misinterpret movement or misalign tools.

- Legal and Compliance Concerns

- Many occupational safety standards now recognize flicker as a hazard.

- Not addressing it may lead to penalties or non-compliance with regulations like OSHA or European EN 12464 standards.

📊 Measuring Flicker

To control flicker, we first need to measure it. Several parameters are used:

- Flicker Percentage

- Difference between maximum and minimum light intensity as a percentage of the average intensity.

- Higher percentages indicate more noticeable flicker.

- Flicker Index

- Provides a better indication of potential visual discomfort.

- Calculated using the waveform of the light output over time.

- Modulation Depth

- Useful for LEDs and high-frequency lighting.

- Indicates how much the brightness changes relative to the baseline.

Tools for measurement:

- Flicker meters or oscilloscopes with photodiodes.

- Advanced light meters now include flicker detection functions.

⚙ Industrial Areas at High Risk

Certain workplaces are more susceptible to flicker and stroboscopic hazards:

- Machine shops: Rotating saws, lathes, and milling machines.

- Conveyor systems: Fast-moving belts in packaging or production lines.

- Food processing plants: Rotating mixers, slicers, or grinders.

- Printing presses: Moving rollers illuminated by fluorescent or LED lights.

Case Study

A metal sheet cutting facility reported several near-miss accidents. Investigation revealed that flickering fluorescent lights caused a stroboscopic effect on fast-moving rollers. Workers misjudged the speed and angle of rotating metal, increasing the risk of injury. Upgrading to high-frequency ballasts and LED lights eliminated the flicker and significantly reduced incidents.

🧠 Human Factors and Sensitivity

Not everyone reacts the same to flicker. Factors influencing sensitivity include:

- Age – Older workers are more affected by high-frequency flicker.

- Eye health – People with certain visual conditions may experience more strain.

- Duration of exposure – Even low-level flicker can cause discomfort over extended periods.

- Task complexity – Precision tasks amplify the impact of visual instability.

💡 Solutions to Minimize Flicker and Stroboscopic Hazards

1. Upgrade Lighting Systems

- LED Lights with Low Flicker Drivers – Modern LEDs with high-quality drivers reduce both visible and invisible flicker.

- Electronic Ballasts for Fluorescents – Replace older magnetic ballasts to eliminate traditional flicker.

2. Maintain Stable Power Supply

- Install voltage stabilizers or uninterruptible power supplies (UPS).

- Avoid using dimmers incompatible with the light type.

3. Optimize Task Lighting

- Use diffused lighting to minimize harsh shadows and flicker perception.

- Consider high-frequency task lights in areas with moving machinery.

4. Monitor and Audit Lighting

- Regularly measure flicker percentage and flicker index in high-risk areas.

- Ensure lighting maintenance includes lamp replacement, ballast checks, and fixture cleaning.

5. Educate Workers

- Train employees to recognize flicker and stroboscopic hazards.

- Encourage reporting of discomfort or unsafe lighting conditions.

📌 Regulatory Guidelines

Several standards address flicker and lighting quality:

- IEEE 1789-2015: Recommendations for flicker in LED lighting.

- EN 12464-1: Lighting of workplaces; includes flicker and stroboscopic considerations.

- OSHA Guidelines: Emphasize the importance of sufficient and stable illumination in industrial settings.

Employers must balance brightness, stability, and comfort to comply with these regulations.

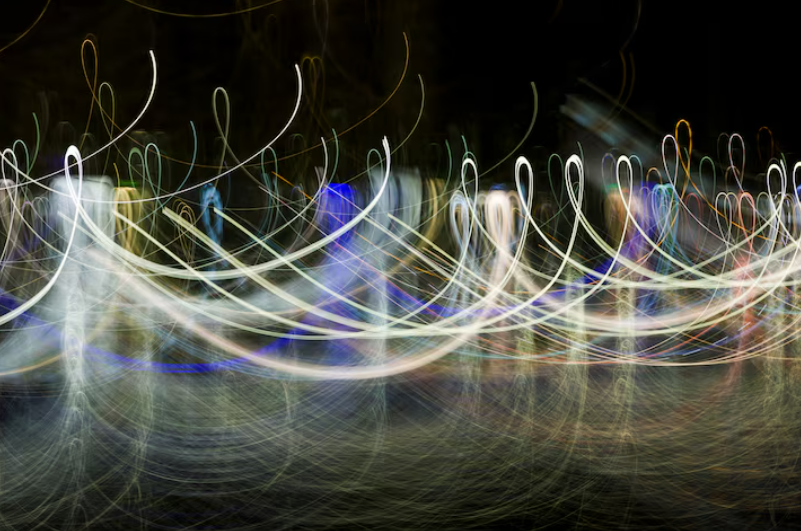

🔍 Visual Examples

- Rotating fan under flickering light: Blades appear frozen.

- Conveyor belt with high-speed packaging: Motion seems intermittent, increasing handling errors.

- Precision assembly under low-quality LED: Workers strain eyes, slowing down production.

Tip: Using high-quality, low-flicker lighting eliminates these optical illusions.

🏭 Benefits of Controlling Flicker and Stroboscopic Effects

- Enhanced Safety – Reduced accidents and near-misses around machinery.

- Improved Productivity – Workers can perform tasks faster and more accurately.

- Better Health and Comfort – Less eye strain, headaches, and fatigue.

- Regulatory Compliance – Avoids fines and promotes safety certifications.

- Energy Efficiency – Modern LED systems consume less power and last longer.

🔧 Implementation Checklist

Here’s a quick action plan for employers:

- Conduct a lighting audit in all critical areas.

- Measure flicker percentage and flicker index.

- Identify high-risk zones for stroboscopic hazards.

- Upgrade to LEDs with certified low-flicker drivers.

- Replace old fluorescent ballasts with electronic versions.

- Educate workers about the hazards and reporting procedures.

- Establish a maintenance schedule for cleaning, replacing, and checking lights.

- Monitor lighting performance and employee feedback regularly.

🌟 Conclusion

Flicker and stroboscopic effects may not scream “danger” the way a spinning blade or heavy machine does, but their impact on safety, productivity, and health is profound.

By understanding the mechanisms, risks, and solutions, workplaces can prevent injuries, reduce fatigue, and ensure compliance with lighting standards.

Remember: stable, flicker-free illumination is not just a convenience—it’s a silent guardian of workplace safety.

Take action today, and light the way toward a safer, healthier, and more productive work environment.

✨ Key Takeaways

- Flicker: Rapid light intensity changes; can be visible or invisible.

- Stroboscopic Effect: Moving objects appear frozen or reversed under flickering light.

- Risks include accidents, eye strain, headaches, fatigue, and reduced productivity.

- High-risk areas: machine shops, conveyors, printing, food processing.

- Solutions: LED upgrades, electronic ballasts, stable power, task lighting, and worker education.

- Standards to follow: IEEE 1789, EN 12464-1, OSHA guidelines.

✅ Pro Tip: Even if your lighting seems fine to the naked eye, invest in flicker measurement tools or consult a lighting professional. Many invisible flickers can silently impact workers’ safety and efficiency.

🔁 Readers also enjoyed these blog posts:

- Safety Management’s Role: The Unsung Hero Behind Every Successful Organization

- Safety Management and Its Responsibilities: Protecting People, Preventing Hazards, and Promoting a Culture of Care

- Benchmarking for Safety Performance: A Key to Continuous Improvement

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”

Turn Any Idea into Viral,

Jaw-Dropping AI Videos in Seconds!