Introduction

Industrial accidents have left a deep mark on history, often causing catastrophic loss of life, environmental destruction, and long-term societal impacts. Many of these disasters have led to changes in safety regulations, industry practices, and government policies. This article examines five of the worst industrial accidents in history, their causes, consequences, and the lessons learned to prevent similar tragedies in the future.

1. Bhopal Gas Tragedy (1984)

What Happened?

On the night of December 2-3, 1984, a toxic gas leak occurred at the Union Carbide pesticide plant in Bhopal, India. Around 40 tons of methyl isocyanate (MIC) gas were released into the air, exposing over 500,000 people to the deadly chemical.

Impact

- Over 15,000 people lost their lives, with thousands dying instantly.

- Hundreds of thousands suffered long-term health effects, including respiratory problems, blindness, and birth defects.

- The surrounding environment was contaminated, affecting water and soil quality for decades.

Causes

- Poor maintenance of safety systems and equipment.

- Lack of proper training and emergency response preparedness.

- Insufficient warning systems for residents.

Lessons Learned

- Stricter safety regulations for chemical plants.

- Better emergency preparedness and response protocols.

- Corporate accountability in industrial operations.

2. Chernobyl Nuclear Disaster (1986)

What Happened?

On April 26, 1986, reactor number four at the Chernobyl Nuclear Power Plant in Pripyat, Ukraine, exploded during a safety test. The explosion released massive amounts of radioactive material into the atmosphere.

Impact

- Immediate deaths of 31 people, with thousands more dying over time from radiation exposure.

- Severe health issues, including cancer and genetic mutations, in the affected population.

- Over 100,000 people evacuated, leaving an entire city abandoned.

- Contaminated land and water sources that remain hazardous even today.

Causes

- A flawed reactor design combined with operator error.

- Lack of proper safety protocols during the test.

- Delayed response from authorities, worsening the crisis.

Lessons Learned

- Improved nuclear safety regulations and international monitoring.

- Better reactor designs and operational training.

- Transparent reporting of nuclear incidents.

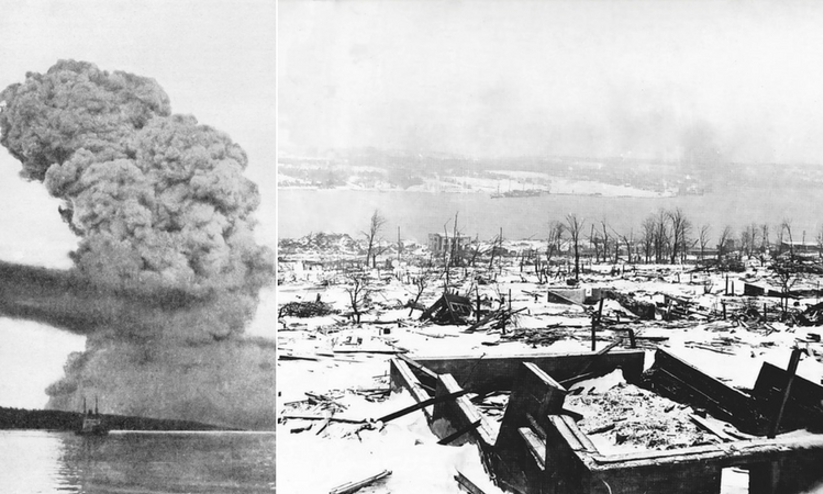

3. Halifax Explosion (1917)

What Happened?

On December 6, 1917, a French cargo ship, SS Mont-Blanc, carrying explosives collided with another ship in Halifax Harbour, Canada. The explosion was one of the largest non-nuclear blasts in history.

Impact

- Approximately 2,000 people killed and 9,000 injured.

- Entire neighborhoods were destroyed, leaving thousands homeless.

- A tsunami followed the explosion, further adding to the destruction.

Causes

- Miscommunication between ships, leading to the collision.

- Lack of safety measures for transporting explosive materials in populated areas.

Lessons Learned

- Enhanced maritime traffic control and communication protocols.

- Improved handling and storage of hazardous materials.

- Strengthened emergency response procedures.

4. Texas City Disaster (1947)

What Happened?

On April 16, 1947, the SS Grandcamp, loaded with ammonium nitrate fertilizer, exploded in the port of Texas City, USA. The blast was one of the deadliest industrial accidents in U.S. history.

Impact

- Over 580 people killed and thousands injured.

- Multiple secondary explosions caused widespread fires and destruction.

- Chemical contamination affected the surrounding environment.

Causes

- Lack of knowledge about the dangers of ammonium nitrate.

- Inadequate storage and handling procedures.

- No safety regulations for shipping hazardous chemicals.

Lessons Learned

- Stricter regulations for the storage and transport of hazardous materials.

- Increased awareness of chemical dangers in industrial settings.

- Emergency planning and risk assessment improvements.

5. Rana Plaza Collapse (2013)

What Happened?

On April 24, 2013, the Rana Plaza garment factory in Dhaka, Bangladesh, collapsed, killing over 1,100 workers and injuring thousands. The building housed multiple factories producing clothes for international brands.

Impact

- The worst industrial disaster in the garment industry.

- Thousands of workers trapped or crushed due to poor construction.

- Families left devastated, leading to global outrage.

Causes

- The building was constructed with substandard materials and unauthorized modifications.

- Overcrowding and poor structural integrity.

- Factory owners ignored warning signs and forced workers to continue working.

Lessons Learned

- Stricter enforcement of building codes and labor rights.

- Improved working conditions and safety inspections.

- Ethical sourcing and corporate responsibility in supply chains.

Conclusion

These five industrial accidents highlight the importance of stringent safety regulations, corporate accountability, and emergency preparedness. Each disaster serves as a reminder that negligence and oversight can lead to tragic consequences. By learning from these past mistakes, industries can implement better safety measures to protect lives, the environment, and communities worldwide.

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”