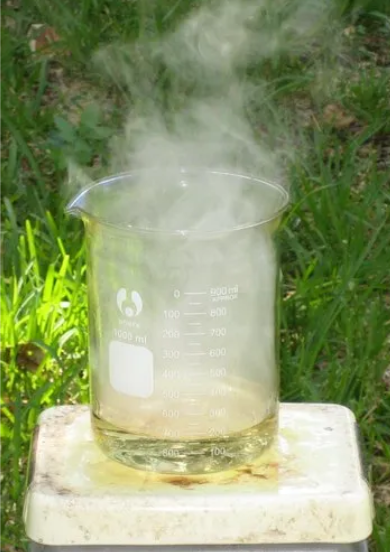

Oleum is the term used to describe fuming sulfuric acids.

Oleum is made in various strengths and consists of SO3 dissolved in 100% H2SO4. Thus, for example, 20% oleum contains 20% SO3 and 80% H2SO4 by weight.

Oleum is normally turbid and off-white in appearance. Depending on strength, the vapor pressure is such that SO3 fumes escape and combine with moisture in the air to form sulfuric acid mist particles that are visible and can create clouds of dense, white fumes.

HAZARDS/HEALTH FFECTS OF OLEUM

Causes eye irritation.

Skin Contact: Prolonged or repeated contact may cause skin irritation. Substance may cause slight skin irritation.

Mists and vapors may cause irritation of the nose and throat with sneezing, sore throat or runny nose. Overexposure may cause increased pulmonary resistance, transient cough and bronchoconstriction. Severe overexposure may result in lung collapse and pulmonary edema (fluid in the lungs) which can be fatal.

STORAGE

Avoid contact with other acids and combustible or oxidizable materials.

Storage areas should be separated from other premises, well ventilated, sheltered from sunlight and sources of heat;

Floorings should be lined with AR Bricklining.

Containers should be kept tightly closed and should be clearly labeled to indicate the contents.

STORAGE TANKS

Generally fixed roof storage tanks are used.

Fabrication of the storage tanks as per standard ( like IS 108)

MOC of shell is generally CS with or without lining as applicable.

A central vent is provided to breath/Exhale air while filling/emptying the tank. Sometimes vents are accompanied with pots containing silica gel to absorb moisture but they are prone to chocking.

Provision of manholes of adequate size to get access for internal inspection & subsequent repair.

Inlet pipelines are recommended to be accompanied with down comers to avoid splash filling.

Separate notice boards are to be displayed at storage locations mentioning precautions to minimize hazards and prevent accidents, correct first aid procedures, correct procedures for cleaning up spills, special instructions to medical personnel in case of an accident.

Proper labeling is to be done at storage tank shell for identification of contents, description of principal hazard (e.g., corrosive)

A dyke wall is to be provided surrounding storage tanks for containment in case of leakage.

Safety showers to be provided at all applicable/multiple locations at the storage site. Thorough washing of affected part of body with water is the first course of action upon contact with acid.

Level of the contents to be measured & indication of same to be provided at control room, high level warning alarm system also to be installed. Where there is a case of holding tanks in continuous process plant, a level control system is to be installed.

Anti-corrosive painting is to be applied at shell.

Proper illumination is to be arranged so visualize storage tank from all the side during dark hours to identify any leakage.

Periodic inspection & maintenance of the storage tank is to be carried out. This includes thickness measurement of shell & patch up of applicable areas.