Cleaner production – Approach

New technique for waste minimization

Continual improvement.

Less effluent – higher margin in profit.

Less risk of release of hazardous chemicals,

Customer satisfaction. (QCDIP).

Organization image – profit – society.

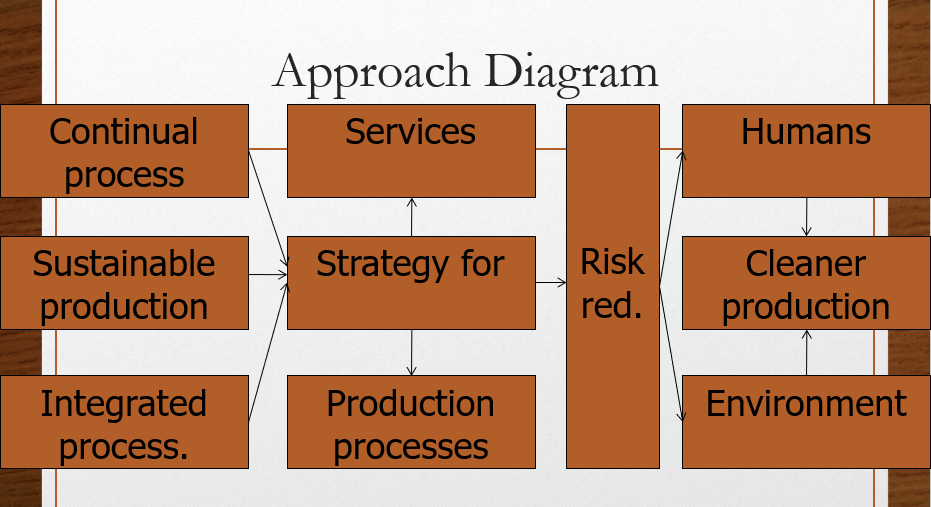

Approach Diagram

Cleaner production – basic components

•Management commitment

•Operators / shop floor people involvement

•Organizational approach.

Cleaner production – techniques

•Major techniques are

- Resource control

• Good house keeping

• Product control

2. By onsite recycling

• Reuse, Recycle , Recovery

3. Energy conservation techniques

• Thermal

• Electrical

1.Resource control

Good house keeping

• Inventory control – FIFO system

• Material handling techniques – avoid spillages etc.

• Loss of material , waste generation , disposal issues, productivity losses.

Product Control by

• Change in Raw materials

• Change in equipments – efficient

• Change in technology

• Change in process.

• Process.

Product Control by

• Change in Raw materials

• Less hazardous / alternate

• Change in equipments – efficient

• Better output

• Change in technology

• Mercury cell to membrane cell

• Change in process. SCSA to DCDA process.

2. By onsite recycling

•Reuse, Recycle , Recovery

Recovery of Solvent based chemicals

Reuse of hazardous chemicals

Recycling of lower fractions

Recovery of the products from residue.

Recovery of catalyst.

Reuse of water

Recycling of off spec material.

3. Energy conservation techniques

•Thermal

• Steam , chilled water , brine , hot water

•Electrical / instrument

• Energy efficient motors , VFD , auto controller

• Process.

• Condensation techniques, endothermic / exothermic reactions

• Route change

• Heat recovery etc.