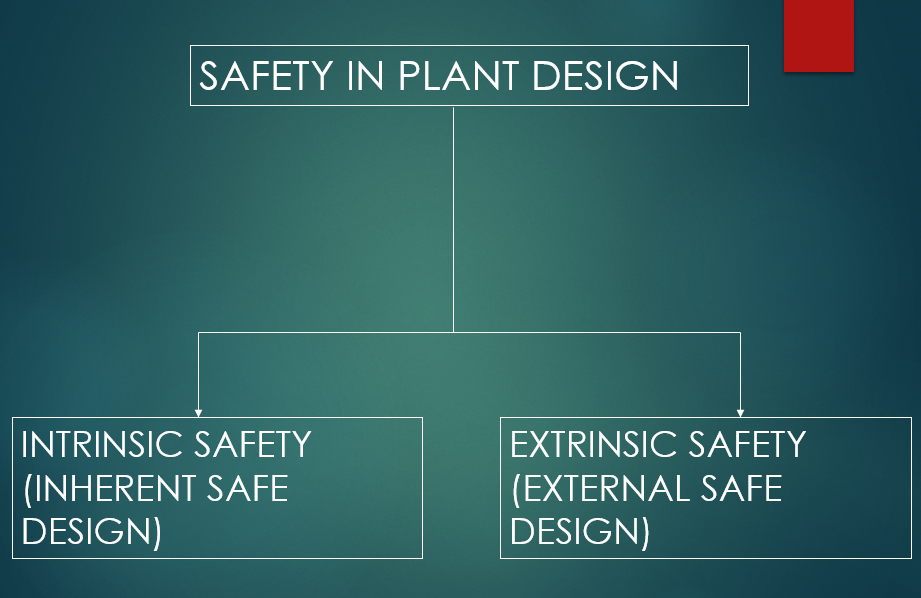

SAFETY IN PLANT DESIGN

INTRINSIC SAFETY:

INTRINSIC SAFETY:

A process in which safe operation is inherent in the nature of the process.

Some principles way of designing are

1. Knock-on effects ( avoiding Domino effects)

2. Intensification ( say hazardous inventory)

3. Substitution ( say of hazardous material by non- or less hazardous material.

4. Simplification ( say avoiding multistreams).

EXTRINSIC SAFETY:

A process which is rendered (make) safe by careful design and the application of safety systems

1.Control systems

2.Automatic shutdown

3.Relief devices

4.Fire fighting systems

5.Blast protection

SITING CRITERIA

GENERAL:

1. Raw material availability

2. Labor availability

3. Ease of Transport

4. Population density in the surrounding area

5. Utilities Facility

6. Sewage, drainage, solid & liquid disposal

SAFETY CONSIDERATION:

- Weather extremes and prevailing winds

2. Emergency equipment access

3. Environmental and waste disposal restrictions during emergencies

4. Location of other hazardous installations in vicinity

5. Adequacy of firefighting water supply

6. Inventory of toxic and hazardous materials

7. Location of highways, waterways, railroad and airplane corridors Availability of emergency response support from adjacent industries and the community

PLANT LAYOUT

Plant Layout is the physical arrangement of equipment and facilities within a Plant. The Plant Layout can be indicated on a floor plan showing the distances between different features of the plant. Optimizing the Layout of a Plant can improve productivity, safety and quality of Products. Unnecessary efforts of materials handling can be avoided when the Plant Layout is optimized. This is valid for: –

- Distances Material has to move

- Distances Equipment has to move

- Distances Operators have to move

- Types of Handling Equipment needed

- Energy required to move items against resistance (i.e. gravity)

GENERAL PRICIPLES:

The layout should be in the sequential order of process flow so that piping run is minimum.

Utility blocks should be located adjacent to the process units.

Arrangements of sections/units to be done considering the prevalent wind direction so that flammable gases should not be carried out to source of ignition.

The main power receiving station should be close to the boundary line so that minimum overhead power lines pass through the plant.

Flares should be located upwind of the process units.

The effluent plant should be located from other plants on the down elevation to facilitate gravity flow.

The fire station & fire water pump house shall be at a safe place away from hazardous area.

– The fire station should be near the main gate with a straight approach to the process units & other critical areas.

– Roads in between for the purpose of access & safety should separate the units. Fire fighting facilities should be provided on these roads.

Provision for future expansion should be considered.

– Statutory requirements like FA 1948, MSIHC Rules 1989, The petroleum act 1934, Electricity Act and other codes like OISD may be followed.

STATUTORY REQUIREMENT

uSection 6 of Factories Act 1948 & Rule 3 of Gujarat Factories Rules 1963 deals with approval of plans. The outlines are here:

– An application for obtaining previous permission for the site on which the factory is to be situated and for the construction & extension of a factory shall be made to Chief Inspector of Factories in Form no.: 1

– No building or premises shall be constructed, extended or taken into use as factory or part of factory unless the previous permission in writing is obtained from Chief Inspector of Factories ( 3A)

– No manufacturing process shall be carried out untill a stability certificate is issued by a competent person in respect of engineering work construction in form no.: 1A has sent to CIF by the occupier (3C)

Section 41-A of Factories Act refers to Constitution of Site Appraisal Committee for the purpose of advising on grant of permission for initial location of factory involving hazardous process.

Section 38 of Factories Act 1948 & Rules 66, 66A & 67 refers to Fire protection:

- Safe means of access to all persons in case of fire

- Fire exits should not be less than 91.4 cm. width nor less than 2 mt. in height.

- Unobstructed access for fire fighting.

MSIHC Rules: Rule no.: 7 Notification of sites:

An occupier shall not undertake any industrial activity unless he has submitted A written report to the concerned authority containing the particulars specified in Schedule 7 at least 3 months before commencing that activity or before such shorter time as the concerned authority may agree and for the purpose of this paragraph an activity in which subsequently there is or is liable to be a threshold quantity or more of an additional hazardous chemical shall be deemed to be a different activity and shall be notified accordingly

Environmental Clearance as per EIA Notification before installation or extension of a project.

Section 12 of Factories Act 1948 & Rule 18 of GFR 1963 refers to Disposal of Effluents.

Rule no.: 5 of EP rules 1986 refers to Prohibitions and restrictions on the location of industries and the carrying on processes and operations in different areas :

The Central government may take into consideration the following factors while prohibiting or restricting the location of industries and carrying on of processes and operations in different areas-

(i) Standards for quality of environment in its various aspects laid down for an area.

(ii) The maximum allowable limits of concentration of various environmental pollutants (including noise) [or an area.

(iii) The likely emission or discharge of environmental pollutants from an industry, process or operation proposed to be prohibited or restricted.

(iv) The topographic and climatic features of an area.

(v) The biological diversity of the area which, in the opinion of the Central Government needs to be preserved.

(vi) Environmentally compatible land use.

ERGONOMIC CONSIDERATION

ERGONOMICS: Effective & convenient relationship between man-material-machineries.

– proper sequence of process routes

– process access to all equipments.

– Means of approach at all locations

– Optimum interdistances.

– proper work space/area

– Ease of handling tools

– proper piping layout, location of valves, joints etc..