Hazard of static charge

Most of the accidents during loading and unloading of tankers, tank cars are caused by lacuna in protections to be provided before starting the operation. Similarly, during filling or emptying out operation of drums, tanks etc. fires & explosions are caused due to accumulated static charge. Lot of care needs be taken during loading/unloading and filling/emptying out operations.

Main hazard of static charge

(a) Fire & Explosion caused by spark discharges containing sufficient energy to ignite any Flammable or explosive vapors & gases which are generally present.

(b) A point of great danger from a static spark is the place where a flammable vapor may be present in the air.

For example:-

- Outlet of a flammable liquid fill pipe.

- A delivery hose nozzle near an open flammable liquid container.

- Around a tank truck fill opening or barrel bung hole.

General Safety Measures

(a) Prevent accidental mixture of flammable liquids. E.g.; Do not mix acetone with kerosene, which will lower flash point of the contents (Acetone is highly volatile)

(b) Do not mix Gasoline with fuel oil which will change the flash point of fuel oil sufficiently to make it hazardous in ordinary use.

(c) In each case the lower flash point liquid can act as a fuse to ignite the higher flash point material.

(d) Control valves on equipment containing flammable liquids should be identified by color tag or both.

(e) The pipe lines be painted or banded with distinctive colors, flow shown clearly. Direction of closing & opening of valves should also be marked clearly.

(f) Each tank should be marked with the name of the product.

(g) Pipe lines from different tanks containing different types / classes of products should be kept separate and preferably separate pumps should be provided.

(h) A portable, approved container should be used for handling small quantities of flammable liquids (up to 10L)

(i) Bonding & grounding systems shall be checked regularly for performance, especially electrically, preferably before each fill.

(j) Exposed parts of the bonding and grounding system should be inspected for parts which have deteriorated because of corrosion or damaged.

(k) Bonds and grounds may be constructed of braided flexible wires because it facilitates inspection & prevents broken wires being concealed.

(l) Electricity becomes a source of ignition where flammable vapors exist, if proper type of electrical equipment has not been installed or has not been maintained. The National / international standards for such atmospheres vis-à-vis electrical equipment be adopted.

(m) Use of special tools designed to minimize the danger of sparks in hazardous locations be considered. Leather faced, plastic and wood tools are free from friction sparks hazard are recommended.

(n) All containers should be aired and tested for toxic and flammable atmosphere before any entry.

(o) Small containers made up of plastic or other non- conductive materials should not be used for filling of MS, Naphtha, Kerosene, Diesel etc.

(p) Do not use plastic bucket or metallic bucket with plastic/plastic coated handles.

(q) Unless test proves otherwise, flammable and toxic mixtures should be assured to be present in all tanks & confined spaces which have contained or have been exposed at any time to flammable liquids.

(r) Oxygen deficiency occurs in closed containers such as a tank which has been closed for a long time and in which rusting has consumed the oxygen.

(s) Combustible gas indicators are to be used for testing. Tests are carried out for presence of any possible toxic gases like CO2 Benzene, hydrogen sulphide & tetra ethyl lead hazards.

(t) No tank should be considered free from the possibility of dangerous vapors as long as it contains sludge or scale.

(u) If a person leaves a tank for a period of time, such as over night, gas tests should be made the next morning before they are permitted to enter. “Work Permit System” is the ideal solution for any work in such atmospheres.

Loading & unloading of tanker

(a) Tanker should be earthed first, before opening the dome (Refer Fig.1 & 2). Metal surface at E- point should be cleaned.

(b) Before filling is started, ensure that the fill pipe has reached the bottom, to avoid splash filling. Once tanker is filled, wait for 5 to 10 min, before removing the earthing clamp.

(c) When tanker is to be unloaded, wait for five minutes after connecting the earthing. Dip rod shall be lowered only after this period. (Relaxation time of 10 / 5 mins)

(d) Avoid Switch loading (when low vapour pressure products are put into a cargo tank containing a flammable vapour from previous usage, e.g. FO loaded into a tank which last carried gasoline.

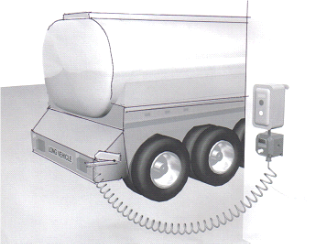

(e) It is safer to use earth monitoring unit. (Refer Fig.1)

Figure 1 – Using Earth monitoring unit

Fig.2 Earthing of tanker, fill pipe and dome

Storage tanks & vessels:

- Earthing of tanks, vessels & pipelines should be properly done. On the flanges of pipelines, proper bonding should be there.

- Gauging or sampling shall be carried out only after surface turbulence is subsided.

- Floating roof tank & inert gas blanketing should be used after proper requirement and suitability.

- Cleaning or gas freeing of tank or vessel by steam or water should be done only after proper earthing.

Filling and Emptying out of drums & containers:

Drums may be metallic or non-metallic. Because metallic drum can be earthed, use of these drums is safe as compared to non-metallic drums. Drums made from HDPE, PVC and other plastic materials are dangerous due to two reasons. First, charge accumulation is more and second, these can not be earthed (like metallic drums). Let us see the safety to be observed during use of drums and containers.

- Drum or vessel to be filled should be earthed with flexible wire & clamp/clip.

- Avoid splash filling. Use feed pipe, which should reach near the bottom.

- As far as possible avoid use of non-metallic pipes and drums. If non metallic drums & pipes are used, provide proper earthing. Bare metallic wire should be wrapped around the non-metallic hose and both ends of the wire should be connected to earthing. It is safer to place the non-metallic drum on earthed metal plate. Earth the metal drum also by earth clip.

- If drum filling is to be done on the weighing scale, platform should be earthed separately.

- During filling, a small vent plug on the top should be kept loose to eliminate pressure build up.

HDPE and other non-metallic drums

As far as possible, avoid use of non-metallic drums for flammable materials. Following care shall be taken during use of such drums.

- Avoid rubbing the drum with any form of clothing or cloth.

- When filling or discharging the contents, the filling/discharge nozzle should be earthed.

- The contents of the drum can become charged by splashing and therefore it is best to fill the drum with the nozzle discharge as close to the bottom of the drum as possible.

- When handling the drum after filling, rough handling should be avoided to minimize splashing.

- Any insulated conductors in the immediate area of the drums should be earthed. This is very important and applies to any metal object which might come into contact with the drum. Tab seals, spanners etc. must not be left on the drum when filling or emptying since they might acquire charge from the drum and discharge with a greater incendive energy than would the drum itself.

- If powder or pellets are filled in non-metallic drum or container, put the earthed metallic rod in the drum. During filling, if possible, this rod shall be moved within the product. This is to ground the charge. Movement during filling will avoid accumulation of charge during filling.