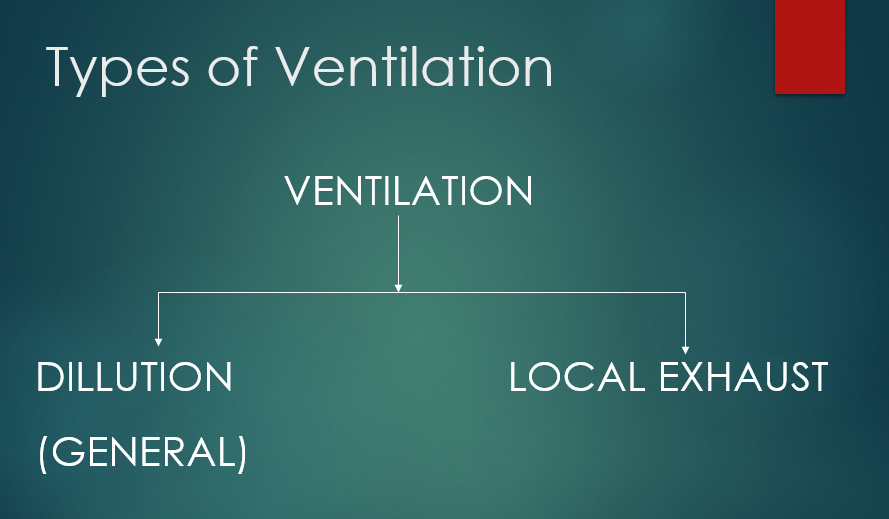

OBJECTIVES OF VENTILATION

- To maintain an adequate oxygen supply in the work area.

2. To control hazardous concentrations of toxic materials in the air.

3. To remove any undesirable odors from a given area.

4. To control temperature and humidity.

5. To remove undesirable contaminants at their source before they enter the work place air.

THERMAL ENVIRONMENT

The thermal environment is concerned with measurement of:

- Temperature

- Humidity

- Air Movement & Content

PHYSIOLOGY OF HEAT REGULATION

Heat Stress

It is the burden or load of heat that must be dissipated if the body is to remain in thermal equilibrium. It is represented by the sum of metabolic heat and environmental heat load. These factors are governed by the temperature, humidity, air movement and the temperature of surrounding.

Heat Strain

It is the physiological or pathological change resulting from heat stress viz. rise in body temperature, sweating, heart rate etc.

HEALTH & SAFETY PROBLEMS

HEALTH PROBLEMS:

Heat stroke due to failure of thermo regulatory mechanism.

Heat exhaustion due to loss of body fluid (with salt) in sweating.

Heat cramps due to sweating and salt loss, drinking much water and failure to replace body’s salt loss.

Fainting due to improper blood circulation to brain.

Transient heat fatigue due to prolonged heat exposure.

SAFETY PROBLEMS:

Accidents due to sweating palms, fogging of safety glasses, accidental contact with hot surface, molten metal, steam etc. and physical discomfort, fatigue & lack of attention.

COUNTER ACTION

ENGINEERING CONTROLS:

To reduce heat of metabolism i.e. gain by M – Reduce level of physical activity by sharing work load with others or by using mechanical means. Schedule cooler periods for work. Increase rest periods.

To reduce air temperature i.e. gain by C – Insulate hot equipment. Improve general & localized ventilation over personnel. Provide exhaust ventilation, local cooling, evaporative cooling etc. If required use ventilated suits against excessive heat.

To reduce radiation temperature i.e. gain by R – Insulate hot equipment. Use reflective or absorptive shielding between the heat source and man. Paint the surface of hot equipment or shield or clothing by using white color for short ware or solar radiation and aluminum color for infra-red radiation. Cover exposed parts of the body.

To reduce high humidity (restriction on loss by E) – Prevent steam leaks. Improve general ventilation. Apply dehumidification in confined spaces. Use ventilated suits for high humidity. Decrease humidity and increase air speed.

PERSONAL MANAGEMENT:

Provide cool water, extra salt where required.

Ensure light weighted loose fitting clothing etc.

If a person is obese or suffering from any cardiovascular disease, physically unfit, suffering from any skin diseases should work carefully in hot condition.

Control of work and rest routine schedule. Use protective safety equipments.

Use protective safety equipments.

STATUTORY REQUIREMENTS

Section 13 under Health of Factories Act 1948 & Rule 18-A of GFR 1963 covers provisions w.r. to ventilation & temperature.

-Effective & suitable provision for adequate ventilation

-The max. WBT of air in a work room at height of 1.5 m above the floor level shall not exceed 300C and adequate air movement of 30 mt./min. shall be provided.

Note

Normally human body maintain the temperature between 36OC to 39.5OC

RH of 40-50% is desirable for comfort, below 30% not desirable as causes dehydration.

20-300C is comfortable temperature.