Type of Accident

Lost Time Injury (20 days lost)

Injured Person

A crane operator

1.0 DESCRIPTION

- A team composed of three crane operators, acting as riggers and under the coordination of the foreman, had to prepare the grommets for rigging on the spreader bar of the offshore installation of a Deck.

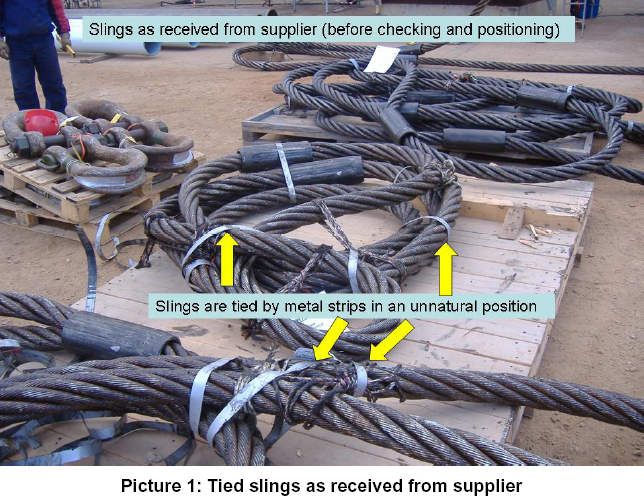

- The grommets (six in all) were coiled on one pallet as received from the supplier. They were coiled by two, one upon the other and strongly tied together with metal straps (picture 1).

- The job to be performed consisted in un-packing the lifting equipment, so as to check and position all slings temporarily on the ground (picture 3).

- The auxiliary rope for the safe retaining of the slings was available on site, but was nor used.

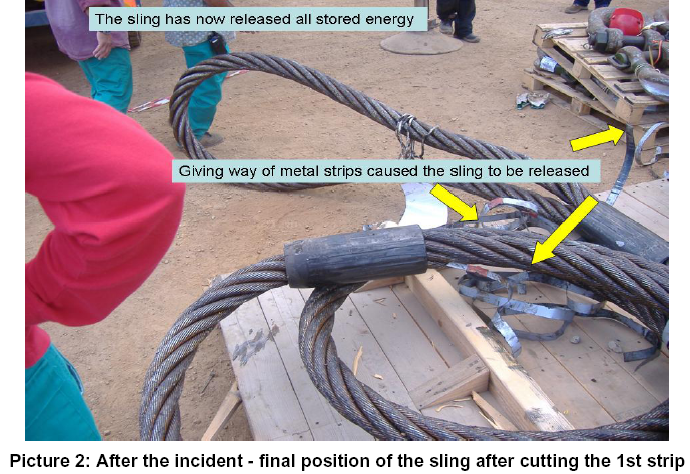

- In order to carry out the job it was necessary to cut and take off the metal straps used by supplier for transportation/storage (pictures 1 and 2).

- The first five slings were un-packed and regularly positioned by one of the team without any difficulties.

- Incident occurred during operations performed by other operator on the sixth sling.

- When the IP cut the first strap the other strap became over-tensioned and gave way. The grommet violently expanded as a “spring” and violently hit the IP on his helmet and ankle causing him to fall down. Immediately aided by Yard Doctor the IP was taken to the hospital for further examination.

2.0 Direct Causes of Accident

- High energy storage as consequence of extreme compression while coiling/packaging to optimize transportation on a small pallet

- Lack of communication on the part of the supplier of relevant hazards (stored energy / slings under tension) and instructions to safely remove metal wraps

- General lack of communication between supplier and user about residual risks related to handling such kind of packages

- Lack of using on the part of operators a device to contain the sling under tension while cutting the wraps

- Underestimation of the risk on the part of the (experienced) worker and error in the estimation of safe distance

- Inadequate pallet, not large enough to handle this kind of package.

3.0 ADDICTIONAL FACTORS

No relevant JSA was prepared

4.0 ROOT CAUSES

General lack of communication system between supplier, client and user about residual risks related to handling such kind of packages.

5.0 CORRECTIVE ACTIONS AND SUGGESTIONS FOR IMPROVEMENT

- Develop a communication system between supplier, client and user to better (safe) handle such kind of packages.

- Require slings supplier to send relevant documentation about the risks or instructions for safely opening the package or unwrap/cut the straps

- Implement a work instruction to safely un-packing metal slings, receiving instructions from supplier

- Use of safe retain systems

- Perform JSA before starting the job

- Carry out a meeting to spread out to personnel both lesson learnt from incident and implementation of work instruction to safe un-packing of metal slings.