Thermal Limits for Comfort and Efficiency in Factories

Walk into any factory on a hot summer afternoon, and you’ll immediately feel it—the heat, the humidity, the heaviness in the air. Now imagine spending 8 to 12 hours every day working in that environment. This is where thermal limits stop being a technical term and start becoming a real human concern.

Thermal conditions inside factories don’t just affect comfort. They influence worker health, productivity, safety, machine efficiency, and even energy costs. Yet, thermal management is still one of the most overlooked aspects of industrial operations.

In this article, we’ll break down what thermal limits really mean, why they matter so much, and how factories can balance comfort and efficiency without burning a hole in their budgets.

What Are Thermal Limits in Factories?

Simply put, thermal limits refer to the acceptable range of temperature, humidity, and airflow within a workplace that allows employees to work safely and efficiently.

These limits are influenced by:

- Ambient temperature

- Relative humidity

- Air movement (ventilation)

- Heat generated by machines and processes

- Nature of work (light, moderate, or heavy)

Thermal comfort isn’t about making factories feel like air-conditioned offices. It’s about creating conditions where the human body can regulate heat without stress.

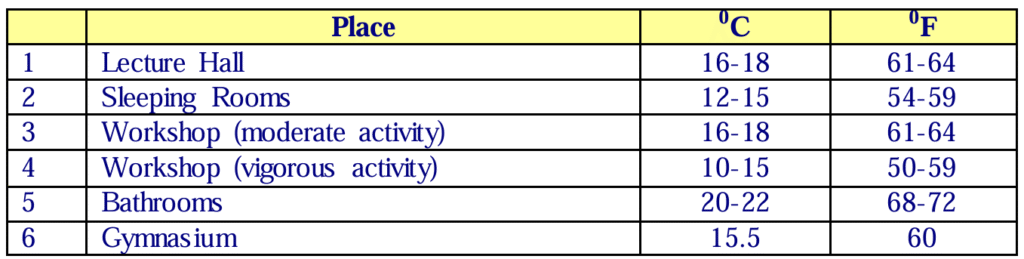

American Ventilating Engineering Association recommends the following ranges as the most acceptable:

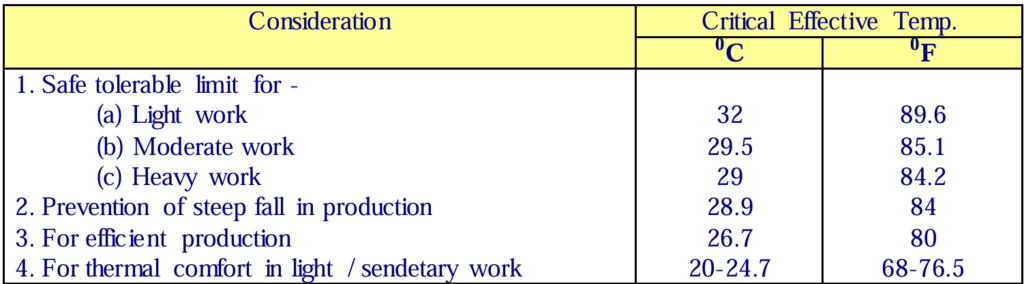

Some recommended upper limit values of comfortable temperature are as follows :

Why Thermal Comfort Matters More Than You Think

Many factory owners focus on machines, output, and deadlines. But the human body is also a “machine”—and it has limits.

1. Worker Health and Safety

Excessive heat can cause:

- Heat exhaustion

- Heat cramps

- Heat stroke (life-threatening)

- Dehydration

- Fatigue and dizziness

When workers feel physically stressed, accident risks increase dramatically—especially around heavy machinery.

2. Productivity and Efficiency

Studies consistently show that productivity drops when temperatures exceed comfort levels. Workers:

- Slow down naturally

- Make more mistakes

- Take more breaks

- Struggle with concentration

A slightly cooler, well-ventilated workspace can increase output without adding manpower.

3. Legal and Compliance Risks

In India, the Factories Act, 1948, and various State Factory Rules mandate:

- Adequate ventilation

- Control of excessive heat

- Measures to prevent heat stress

Ignoring thermal limits can result in:

- Legal notices

- Penalties

- Factory shutdowns

- Worker complaints and inspections

Recommended Thermal Limits for Factory Environments

Thermal comfort depends on the type of work being performed.

General Temperature Guidelines

- Light work (assembly, inspection): 20°C – 27°C

- Moderate work (machine operation): 18°C – 25°C

- Heavy work (foundries, forging): As low as practicable with strong ventilation

Relative Humidity

- Ideal range: 40% – 60%

- High humidity reduces sweat evaporation, increasing heat stress.

Air Velocity

- Proper air movement helps remove body heat.

- Ceiling fans, exhaust systems, and cross-ventilation are essential.

Comfort is not a luxury—it’s a performance requirement.

Heat Sources Inside Factories

To control thermal limits, you must first understand where the heat comes from.

1. Machinery and Equipment

- Furnaces

- Boilers

- Compressors

- Motors and generators

Poorly maintained machines generate excess heat.

2. Industrial Processes

- Welding

- Casting

- Chemical reactions

- Drying and curing operations

3. Building Design

- Low roofs

- Poor insulation

- Metal sheet structures

- Inadequate ventilation

4. Environmental Factors

- Hot outdoor temperatures

- Seasonal heat waves

- High humidity regions

Health Effects of Exceeding Thermal Limits

When thermal limits are ignored, workers’ bodies struggle to maintain internal temperature.

Common Symptoms

- Excessive sweating

- Headaches

- Nausea

- Muscle cramps

- Rapid heartbeat

Severe Conditions

- Heat exhaustion

- Heat syncope (fainting)

- Heat stroke (medical emergency)

Heat-related illnesses often go underreported—but they silently reduce workforce reliability.

Impact on Machinery and Energy Efficiency

Thermal limits don’t affect only humans.

Machinery Problems

- Overheating motors

- Reduced lubrication efficiency

- Increased wear and tear

- Frequent breakdowns

Energy Losses

- Inefficient cooling systems

- Overuse of fans or ACs

- Heat leakage due to poor insulation

Ironically, poor thermal management increases both maintenance costs and energy bills.

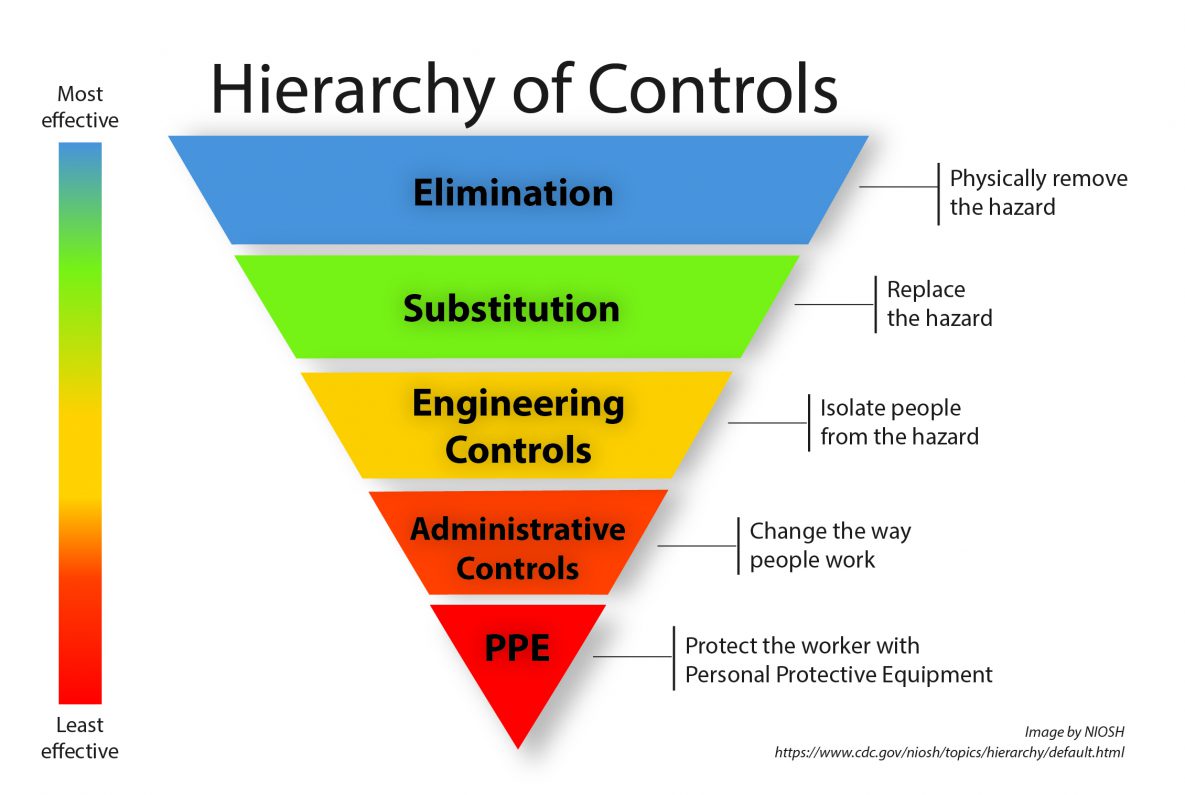

Practical Measures to Control Thermal Conditions

You don’t need expensive solutions to improve thermal comfort. Smart planning goes a long way.

1. Natural Ventilation

- Roof ventilators

- Louvers and wall openings

- High-level exhaust vents

Hot air naturally rises—use physics to your advantage.

2. Mechanical Ventilation

- Exhaust fans near heat sources

- Local exhaust ventilation (LEV)

- Make-up air systems

Target heat at its source instead of cooling the entire building.

3. Insulation and Heat Shields

- Insulate hot pipelines

- Use reflective barriers near furnaces

- Insulated roofing sheets

This reduces radiant heat exposure significantly.

4. Process Optimization

- Schedule high-heat processes during cooler hours

- Automate high-temperature tasks

- Reduce machine idle time

5. Cooling Solutions

- Spot cooling (air coolers or AC near workstations)

- Evaporative cooling systems

- Chilled air for control rooms

Avoid overcooling—it wastes energy and creates discomfort.

Administrative Controls for Thermal Comfort

Engineering controls alone aren’t enough.

Work–Rest Cycles

- Short breaks in cool areas

- Job rotation for heat-intensive tasks

Hydration Programs

- Easy access to drinking water

- Electrolyte solutions in extreme heat

Training and Awareness

- Teach workers early signs of heat stress

- Encourage reporting without fear

Role of PPE in Thermal Environments

Personal Protective Equipment is necessary—but it can also increase heat stress.

Best Practices

- Use breathable fabrics

- Avoid unnecessary layering

- Provide cooling vests where needed

Balance protection with thermal comfort.

Designing Factories for Thermal Efficiency

New factories have a golden opportunity to get it right from the start.

Smart Design Features

- Higher roof height

- North–south orientation

- Skylights with heat-reflective glass

- Green roofing or solar panels

A well-designed building reduces lifetime cooling costs.

Thermal Comfort and Sustainability

Improving thermal limits isn’t just about comfort—it’s also about sustainability.

Benefits

- Lower energy consumption

- Reduced carbon footprint

- Longer equipment life

- Happier, healthier workforce

Comfort and efficiency go hand in hand.

Common Mistakes Factories Make

Despite good intentions, many factories fail due to:

- Relying only on ceiling fans

- Ignoring humidity

- Cooling entire spaces instead of hotspots

- Delaying maintenance of ventilation systems

Thermal comfort requires continuous monitoring, not one-time fixes.

How to Assess Thermal Conditions in Your Factory

Regular assessments help prevent problems.

Tools and Methods

- Dry bulb and wet bulb thermometers

- Heat stress index (WBGT)

- Worker feedback surveys

- Energy audits

Data-driven decisions always outperform assumptions.

The Human Side of Thermal Limits

At the end of the day, factories don’t run on machines alone—they run on people.

When workers feel physically comfortable:

- Morale improves

- Absenteeism drops

- Retention increases

- Quality of work improves

Thermal comfort is one of the simplest ways to show employees that their well-being matters.

Conclusion: Comfort Is Not Optional—It’s Essential

Thermal limits in factories are not just technical guidelines. They are a critical link between safety, productivity, efficiency, and compliance.

By understanding heat sources, respecting human limits, and implementing practical controls, factories can:

- Protect worker health

- Improve output

- Reduce energy waste

- Stay legally compliant

In today’s competitive industrial world, comfort is no longer a cost—it’s an investment.

If your factory feels uncomfortably hot, chances are it’s silently costing you more than you realize.

🔁 Readers also enjoyed these blog posts:

- Safety Management’s Role: The Unsung Hero Behind Every Successful Organization

- Safety Management and Its Responsibilities: Protecting People, Preventing Hazards, and Promoting a Culture of Care

- Benchmarking for Safety Performance: A Key to Continuous Improvement

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”

Turn Any Idea into Viral,

Jaw-Dropping AI Videos in Seconds!