Introduction

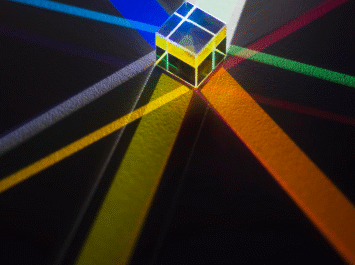

Workplace safety is a responsibility that goes beyond providing personal protective equipment (PPE) or enforcing safety protocols. One of the most effective yet often overlooked tools for preventing accidents is the strategic use of colours and signs.

From factories and construction sites to hospitals and offices, the way we communicate hazards visually can make the difference between a safe environment and a serious accident. In this article, we’ll dive deep into colours, signs, and their roles in accident prevention, helping you understand how to create safer workplaces.

🎨 Why Colours Matter in Accident Prevention

Colours are not just for aesthetics—they are a powerful communication tool. Humans can process visual information faster than text or verbal instructions, and using standardized colours helps workers instantly recognize hazards, instructions, or safe zones.

Here’s why colours are crucial:

- Instant Recognition

- A bright red sign immediately signals danger or the need to stop.

- Yellow alerts you to caution.

- Universal Understanding

- Standardized colours in industrial and safety settings are recognized globally, making workplaces safer even for non-native speakers.

- Psychological Impact

- Colours influence behavior. Red triggers attention, green signals safety, and blue conveys mandatory action.

⚠️ Common Safety Colours and Their Meanings

According to the International Organization for Standardization (ISO 3864) and national standards like the Factories Act in India, the following colours are widely used for safety purposes:

| Colour | Meaning | Examples |

|---|---|---|

| Red | Danger, prohibition, fire equipment | Fire extinguishers, emergency stops, do not enter areas |

| Yellow / Amber | Caution, potential hazards | Slippery floors, forklift traffic, electrical hazards |

| Green | Safe condition, first aid, emergency exits | Safety showers, exit signs, first aid kits |

| Blue | Mandatory action | Wear PPE, safety helmets, hearing protection |

| Black & White | Housekeeping, traffic marking | Floor lines, walkway boundaries, directional markings |

| Orange | Warning, dangerous machinery | Moving parts, pinch points, conveyor belts |

🔴 Red – The Colour of Danger

Red is universally associated with hazards. It commands attention and is used to signal immediate action or stop.

Common uses of red:

- Fire extinguishers and fire alarms

- Stop buttons on machinery

- Danger zones around electrical panels

- Prohibition signs like “No Entry”

Best practices:

- Use bright red with white lettering for maximum visibility.

- Avoid overusing red to prevent desensitization.

⚠️ Yellow – The Colour of Caution

Yellow signals potential hazards that are not immediately life-threatening but require attention. It’s often paired with black symbols or stripes for high contrast.

Examples of yellow in safety:

- Slippery floor signs

- Warning triangles near moving machinery

- Electrical hazard indicators

- Forklift traffic zones

Pro Tip: Use reflective materials for yellow signs in low-light areas to maintain visibility.

🟢 Green – The Colour of Safety

Green represents safe conditions and guidance. It reassures workers and indicates where to go or what to use in emergencies.

Examples:

- Emergency exits and escape routes

- First aid stations

- Safety showers and eye wash stations

- Safe operating zones

Why it works: Green is psychologically calming and encourages compliance without panic.

🔵 Blue – The Colour of Mandatory Actions

Blue conveys compulsory instructions. It tells workers what they must do to maintain safety.

Common uses of blue:

- PPE requirements (helmets, gloves, ear protection)

- Safety instructions at workplaces

- Areas where certain tasks are mandatory

Tip: Always combine blue signs with clear pictograms to avoid misinterpretation.

⚫ & ⚪ Black and White – Organizational Guidance

These colours are often used for floor markings, directional arrows, or housekeeping lines.

Examples:

- Marking pedestrian walkways vs. vehicle lanes

- Indicating storage areas

- Floor lines around hazardous equipment

Pro Tip: Maintain high contrast to make these markings visible under poor lighting conditions.

🟧 Orange – Machinery Warning

Orange is a warning colour for potentially dangerous machinery or equipment. It’s a step above yellow, indicating higher risk areas.

Examples:

- Moving conveyor belts

- Pinch points or rotating parts

- Machinery under maintenance

Best practice: Pair orange with black stripes or symbols for clarity.

🪧 Types of Safety Signs

Colours alone are not enough. Signs must communicate clear messages using symbols, words, or both.

1. Prohibition Signs

- Shape: Circular with a red border and diagonal line

- Meaning: Actions that are not allowed

- Examples: “No Smoking,” “Do Not Enter,” “No Open Flames”

2. Warning Signs

- Shape: Triangular with a yellow background and black border/symbol

- Meaning: Potential hazards that require caution

- Examples: “High Voltage,” “Slippery Floor,” “Forklift Crossing”

3. Mandatory Signs

- Shape: Circular with blue background and white symbol

- Meaning: Actions that must be followed

- Examples: “Wear Hard Hat,” “Use Hearing Protection”

4. Safe Condition Signs

- Shape: Rectangular or square with green background and white symbol/text

- Meaning: Indicate safe areas, first aid, and emergency facilities

- Examples: “Emergency Exit,” “First Aid Kit,” “Safety Shower”

5. Fire Safety Signs

- Shape: Rectangular with red background and white symbol/text

- Meaning: Location of fire-fighting equipment

- Examples: Fire extinguisher, fire hose reel, fire alarm points

🌍 International Standards and Codes

Using standardised colours and signs ensures global compliance and prevents confusion. Some major references include:

- ISO 3864 – International standard for safety colours and signs

- OSHA (Occupational Safety and Health Administration) – U.S. regulations for workplace safety

- Indian Factories Act & State Rules – Prescribe minimum signage and colour codes

- ANSI Z535 – U.S. standard for safety colours, signs, and symbols

By following these standards, organizations ensure consistency and instant recognition across different locations and industries.

🏭 Application of Colours and Signs in Different Workplaces

1. Factories and Industrial Plants

- Red for emergency stops, fire fighting equipment

- Yellow for moving machinery and forklifts

- Green for safe walkways and first aid areas

- Blue for PPE mandates

2. Construction Sites

- Orange for heavy machinery

- Yellow for hazard zones

- Blue for helmets and safety gear

- Red for fire extinguishers

3. Hospitals and Laboratories

- Green for emergency exits and first aid

- Red for fire alarms

- Yellow for biohazard or chemical warning areas

- Blue for mandatory lab coats and gloves

4. Offices and Public Spaces

- Red for fire alarms and extinguishers

- Green for emergency exits

- Yellow for slippery surfaces or maintenance areas

✅ Best Practices for Effective Safety Signage

- Use Pictograms – Combine colours with clear symbols to overcome language barriers.

- Ensure Visibility – Place signs at eye level, well-lit, and unobstructed.

- Maintain Consistency – Use the same colour and symbol conventions throughout the facility.

- Use Durable Materials – Signs should withstand weather, chemicals, and physical impact.

- Periodic Training – Workers must understand the meaning of colours and signs.

- Regular Audits – Inspect and replace faded or damaged signs immediately.

💡 The Psychology of Colours in Safety

- Red triggers urgency and immediate attention.

- Yellow promotes caution without panic.

- Green reassures and guides.

- Blue enforces compliance.

Understanding this psychological impact ensures that workers respond correctly even under stress, reducing the chance of accidents.

🚨 Common Mistakes to Avoid

- Overloading Signs – Too many signs in one place can confuse workers.

- Ignoring Standard Codes – Using non-standard colours or symbols can be misleading.

- Poor Placement – Signs hidden behind equipment or machinery lose their purpose.

- Neglecting Maintenance – Faded or dirty signs reduce visibility and effectiveness.

🌟 Key Takeaways

- Colours and signs are critical for accident prevention.

- Standardized colours improve recognition and reduce workplace hazards.

- Signs should be clear, visible, and compliant with international standards.

- Regular maintenance, training, and audits are essential for effectiveness.

- Investing in proper signage saves lives, prevents accidents, and improves workplace efficiency.

✍️ Final Thoughts

Every workplace can benefit from strategically implemented colours and signs. They are inexpensive tools with high impact, guiding workers, alerting them to hazards, and helping prevent accidents before they occur.

If you are a safety officer, manager, or employer, take a walk around your workplace today:

- Are all signs visible and compliant?

- Are hazard zones clearly marked with proper colours?

- Is safety information easily understandable to everyone?

By following the recommended standards for colours and signs, you not only comply with laws but also protect your most valuable asset—your people.

A safe, well-marked workplace is a productive workplace. Don’t wait for an accident to realize the power of colours and signs!

✅ Pro Tip: Combine safety signs with floor markings and LED indicators in high-risk areas to further reduce accidents and enhance visual guidance.

🔁 Readers also enjoyed these blog posts:

- Safety Management’s Role: The Unsung Hero Behind Every Successful Organization

- Safety Management and Its Responsibilities: Protecting People, Preventing Hazards, and Promoting a Culture of Care

- Benchmarking for Safety Performance: A Key to Continuous Improvement

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”

Turn Any Idea into Viral,

Jaw-Dropping AI Videos in Seconds!