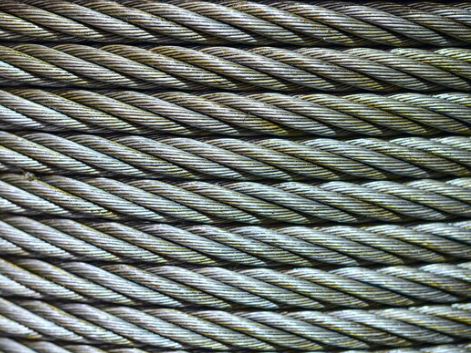

A safety talk on wire rope inspection emphasizes the importance of regularly examining wire ropes to ensure their safe use in lifting and rigging operations. It covers key aspects such as checking for signs of wear, corrosion, broken wires, kinks, or deformation that could compromise the rope’s strength. The talk also highlights the need to follow manufacturer guidelines on acceptable levels of wear, proper lubrication to prevent rust, and the importance of discarding ropes that do not meet safety standards. Regular inspections help prevent accidents by ensuring that only ropes in good condition are used in lifting tasks.

Here’s a safety talk on wire rope inspection, emphasizing essential points for ensuring the safety and functionality of wire ropes:

25-Point Safety Talk on Wire Rope Inspection:

1. Understand the Purpose of Wire Rope Inspection

Wire rope inspection ensures the rope’s integrity and safety in lifting, rigging, and other load-handling applications.

2. Inspect Before Each Use

Always conduct a thorough visual inspection before using wire rope to identify potential issues.

3. Wear Proper PPE During Inspection

Use gloves, safety glasses, and other appropriate PPE to protect yourself while handling the wire rope.

4. Look for Broken Wires

Count broken wires in a single strand or lay length. Excessive broken wires can weaken the rope and make it unsafe.

5. Check for Abrasion

Inspect the rope for signs of wear from rubbing against surfaces, which can reduce its strength.

6. Identify Corrosion

Look for rust, pitting, or discoloration on the wire rope, indicating corrosion that could weaken the structure.

7. Check for Deformation

Inspect for kinks, twists, or other deformities that indicate compromised wire rope structure.

8. Evaluate Reduction in Diameter

Measure the rope’s diameter along various sections. A significant reduction may indicate internal damage.

9. Examine End Fittings

Inspect the sockets, hooks, or thimbles for wear, cracks, or other signs of damage.

10. Check for Birdcaging

A “birdcage” appearance in the wire rope indicates that internal strands have pushed outward, compromising strength.

11. Look for Core Protrusion

Internal core displacement or protrusion is a serious defect requiring immediate rope replacement.

12. Inspect for Heat Damage

Discoloration, fused strands, or melted sections indicate exposure to high temperatures and compromised strength.

13. Pay Attention to Load History

Review the rope’s usage history, including load weight, frequency of use, and environmental conditions.

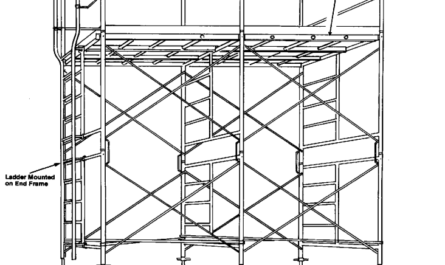

14. Check for Fatigue Failures

Bending fatigue can cause the rope to fail near the fittings or over repeated contact points.

15. Monitor Vibration Damage

Inspect areas where the wire rope may have experienced excessive vibration, leading to wear.

16. Avoid Overloading

Never exceed the wire rope’s rated load capacity, which can accelerate damage and cause failure.

17. Properly Lubricate the Wire Rope

Regular lubrication helps reduce friction, protect against corrosion, and extend the life of the rope.

18. Document Inspection Findings

Keep a record of inspection results, including the condition of the rope, any defects found, and maintenance performed.

19. Train Personnel on Inspection Procedures

Ensure that all workers involved in using or inspecting wire ropes understand the proper inspection techniques and safety measures.

20. Know When to Discard the Wire Rope

Discard the rope if it shows signs of excessive broken wires, diameter reduction, core protrusion, or severe corrosion.

21. Inspect the Rope During Use

Perform additional inspections if the rope experiences unusual loading, high temperatures, or other extreme conditions.

22. Pay Special Attention to Critical Areas

Focus on sections of the rope that experience the most stress, such as near end fittings or contact points.

23. Use the Appropriate Inspection Tools

Utilize tools like calipers for measuring diameter and magnifiers for close-up inspection of wire strands.

24. Comply with Industry Standards and Regulations

Follow guidelines set by relevant regulatory bodies, such as OSHA or ISO, for wire rope inspection and maintenance.

25. Replace the Rope if Doubt Exists

If there’s any uncertainty about the wire rope’s integrity, it’s safer to replace it than risk a potential failure.

Regular and thorough inspections, combined with proper training and adherence to safety standards, will help maintain the safe operation of wire ropes in the workplace.

“Start Your Website Journey Today – Exclusive Hostinger Discounts!”